Seam sealers, crucial for automotive collision centers, protect vehicle structural integrity by creating airtight bonds against water and air intrusion. Advanced technology integration, including smart sealants with AI and sensors, revolutionizes repair efficiency and accuracy, reducing manual labor and human error. These innovations offer real-time data analysis, predictive maintenance, and customized solutions, enhancing productivity and ensuring repaired vehicles meet high-quality standards.

Seam sealers, essential tools in industrial applications, play a pivotal role in sealing joints, protecting against leaks, and ensuring product integrity. As technology advances, smart sealants integrated with innovative solutions are transforming the landscape of industrial processes. This article explores the basic functionality of seam sealers, delves into the benefits of technology integration, and provides insights into the future of industrial applications by combining these powerful tools. Discover how this fusion enhances efficiency, precision, and overall productivity.

- Understanding Seam Sealers: The Basic Functionality and Their Role

- Technology Integration: Enhancing Efficiency and Precision with Smart Sealants

- Benefits of Combining Seam Sealers and Technology: A Glimpse into the Future of Industrial Applications

Understanding Seam Sealers: The Basic Functionality and Their Role

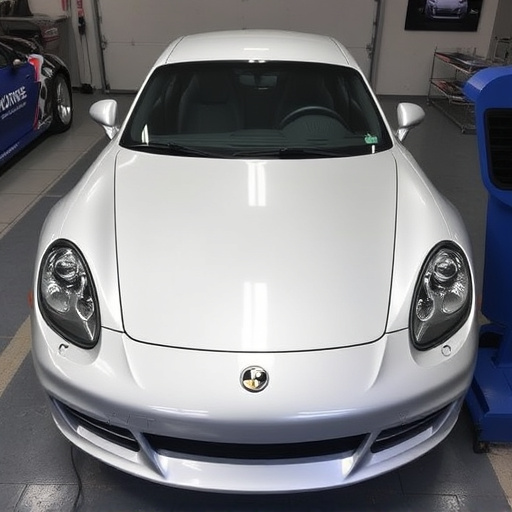

Seam sealers are integral tools in the automotive industry, particularly in car damage repair and collision repair centers. Their primary functionality is to create a robust bond between two or more materials, ensuring that joints and seams remain airtight and durable. In vehicle body repair, these sealers play a crucial role in maintaining structural integrity by preventing water, air, and other elements from infiltrating, which can compromise the strength and safety of the vehicle over time.

By applying seam sealer, professionals in collision repair centers enhance the quality and longevity of their work. This is especially significant in repairing complex car damage scenarios, where precise sealing ensures that vehicles return to their pre-accident condition. The integration of advanced technology in seam sealer application further benefits both repair processes and end products, offering more precise outcomes, faster turnaround times, and enhanced overall vehicle performance.

Technology Integration: Enhancing Efficiency and Precision with Smart Sealants

Technology Integration: Enhancing Efficiency and Precision with Smart Sealants

In today’s digital era, the integration of technology into traditional industries like automotive repair is revolutionizing the way we approach even the smallest tasks. When it comes to seam sealing, smart sealants equipped with advanced sensors and AI capabilities offer unprecedented precision and efficiency. These innovative products can precisely detect and fill gaps and cracks, ensuring every seam is sealed tightly and evenly. This not only reduces the time and labor required for manual sealing but also minimizes the risk of human error.

For instance, in car body restoration and vehicle collision repair processes, smart sealants play a pivotal role in achieving seamless results. Body shop services can benefit from the real-time data and feedback provided by these advanced materials, allowing technicians to make informed adjustments on the fly. This integration streamlines workflows, enhances productivity, and ultimately delivers superior quality outcomes for customers, ensuring every repaired vehicle looks as good as new.

Benefits of Combining Seam Sealers and Technology: A Glimpse into the Future of Industrial Applications

Combining seam sealers with technology integration offers significant advantages for industrial applications, paving the way for a future where efficiency and precision reign supreme. This innovative approach leverages advanced materials science and digital solutions to create seamless (pun intended) processes that enhance productivity while reducing costs. For instance, smart sensors embedded in sealing systems can monitor environmental conditions, ensuring optimal performance during auto collision repair or automotive repair procedures, including intricate auto glass repair tasks.

These technological enhancements allow for real-time data analysis, predictive maintenance, and customized sealing solutions. By integrating AI and machine learning algorithms, seam sealers can adapt to different materials and complex geometries, making them indispensable in high-precision tasks like those encountered in automotive manufacturing and repair. Such advancements not only streamline operations but also contribute to the development of more durable and reliable products across various industries.

Integrating technology with seam sealers opens up a world of possibilities for industrial applications, offering enhanced efficiency, precision, and productivity. By leveraging smart materials and digital solutions, manufacturers can achieve better sealing performance, reduce human error, and streamline production processes. The future of industrial sealing looks promising, with seamless (no pun intended) integration as the key to unlocking new levels of innovation and competitiveness in various sectors.